HPP Introduction

Introduction to Ultrahigh Pressure Sterilization Technology

HPP, also known as ultra-high pressure processing technology, refers to placing food sealed in an elastic container in a pressure system with water or other liquids as the pressure transmission medium, and then subjecting it to a pressure treatment of 100~600Mpa to achieve the purpose of sterilization, enzyme inactivation and improvement of food functional properties at room temperature or even lower.

Thermal sterilization technology has some insurmountable shortcomings, which can damage the color, aroma, functionality and nutritional components of some products, especially heat-sensitive products. After thermal sterilization, fresh products lose their original freshness and even produce odors, affecting product quality. Analysis: HPP is one of the most researched and commercialized non-thermal processing technologies. It overcomes the above-mentioned shortcomings of thermal sterilization and has the following advantages: retaining heat-sensitive nutrients; extending the shelf life of food without the use of additives and preservatives; maintaining food freshness; and a new trend in healthy living.

Brief Introduction of Ultra-High Pressure Thawing Technology

Ultra-high pressure thawing is a method of rapidly thawing frozen food using high pressure technology. The principle is to quickly release the water in frozen food from ice crystals by applying high pressure in a short period of time, so that the food can be thawed quickly. Generally, the pressure range of ultra-high pressure thawing is 100-600Mpa, and the thawing speed is several times faster than traditional thawing, while maintaining the quality and nutritional content of the food.

Ultra-high pressure thawing also has two forms: ultra-high pressure assisted thawing (PAT for short) and ultra-high pressure induced thawing (PIT for short). The former corresponds to the DCBA process in Figure 1, and the latter corresponds to the GFEA process. In the ultra-high pressure assisted thawing (PAT) process, the pressure causes the phase change point (freezing point of water) to drop, and the phase change is basically carried out under constant pressure and constant temperature.

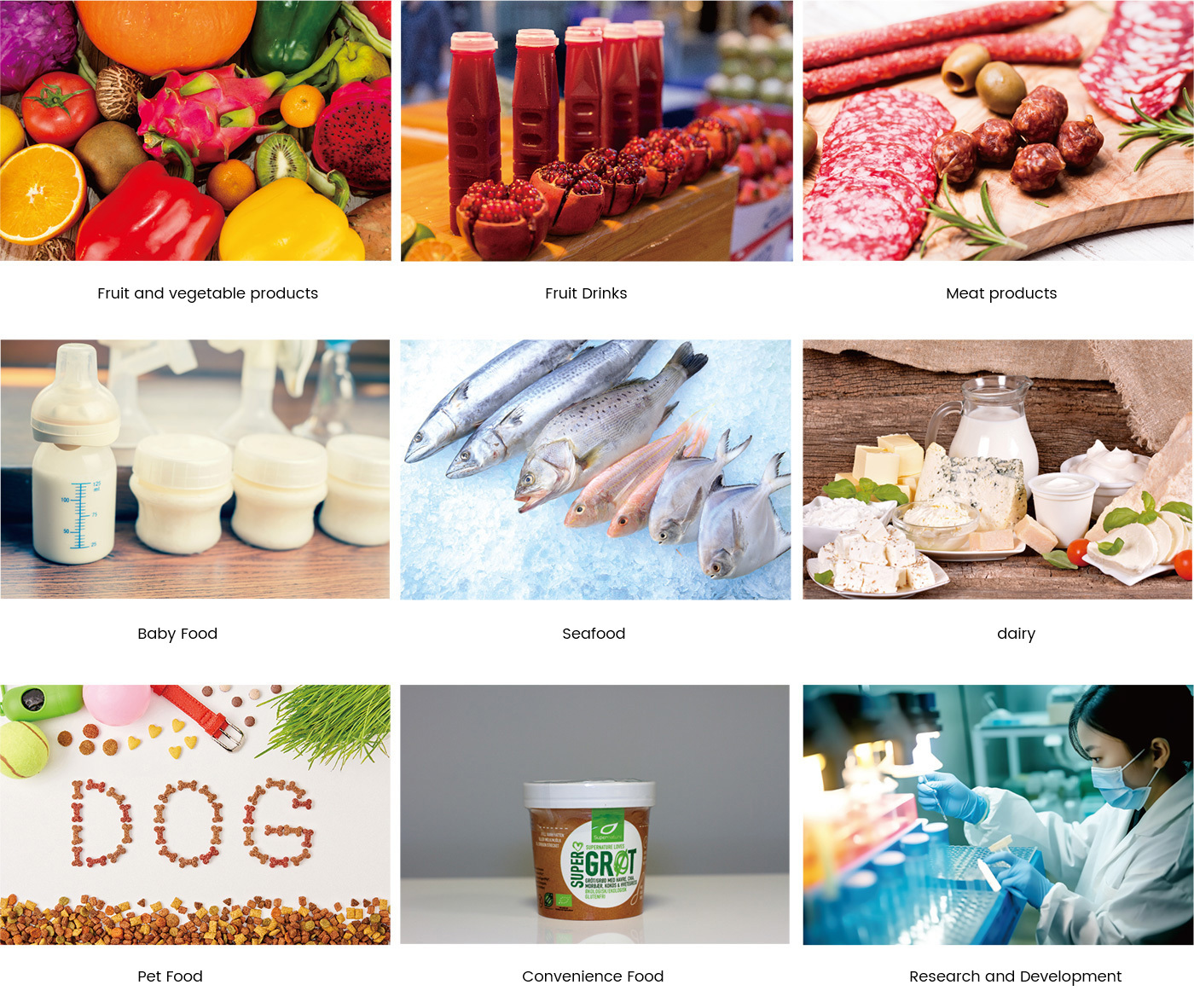

Application of Ultrahigh Pressure Sterilization