Application of HPP Ultrahigh Pressure Processing in Meat Products

Ultra-high pressure processing is a cost-effective method to protect meat products from pathogens such as Listeria monocytogenes, Salmonella, pathogenic E. coli and Campylobacter. Since the water pressure is distributed in all directions, the pressure transmission during the process is uniform and immediate, and the effect on microorganisms is independent of the product size.

HPP is used in a variety of meat products, such as ready-to-eat cooked meats, cured meats, cooked and cured sausages, conditioned meats and aquatic products.

Consumers are increasingly concerned about chemical preservatives in food, and HPP can eliminate preservatives such as sodium benzoate and sodium diacetate from the formulation. At the same time, HPP meat products can reduce the sodium content in the formulation, especially in processed meats, and reducing salt intake is currently a global health challenge.

Flexible plastic materials used for pre-packaging HPP foods must be waterproof and airtight, and be able to be compressed by at least 15%. Certain material specifications, such as oxygen and moisture barriers, are critical to extend shelf life.

Because products are HPP processed after packaging, costly food safety recalls that damage your brand reputation are avoided.

Advantages

• Non-thermal processing after packaging ensures food safety

• Scientifically proven, regulatory approved – effectively kills Listeria monocytogenes

• Effectively reduces the overall microbial count of the product

• Reduces testing frequency

• Improves product quality and extends shelf life.

• Meets consumer demand for low sodium, no preservatives, clean label

• Avoids product recalls, protects brands, businesses and consumers

Product concept evaluation and application services

Process Validation

Start with access to our experts at the HPP Application Center, where we will provide comprehensive support from initial concept evaluation to in-house inoculation challenge experiments, from product formulation, packaging guidance to HACCP establishment, designed to accelerate your HPP product to market.

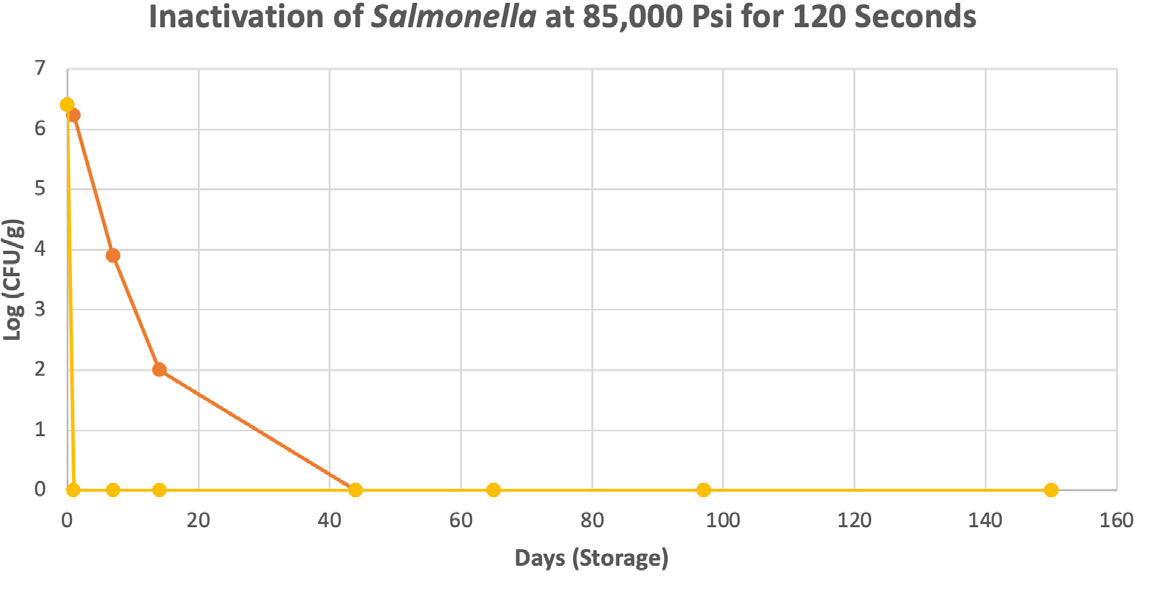

Effect of HPP on Microorganisms

Effect of HPP on Listeria, E. coli and Salmonella inoculated in roast beef

Aw 0.9803 (n=3)

Advantages of HPP ultra-high pressure sterilization

pure physical sterilization

HPP ultra-high pressure sterilization process without adding any chemical preservatives to maintain the original nutritional content and sensory properties of food

Extended shelf life

Because HPP technology can kill microorganisms and inhibit their reproduction, it can significantly extend the shelf life of food.

Efficient sterilization

Can kill all kinds of pathogenic bacteria in food, mold and yeast and other microorganisms to ensure the safety of food

Broad application industry

Suitable for fruit and vegetable juice, meat products, dairy products, fruit and vegetable puree, prefabricated vegetables and other food processing and preservation

Energy saving and environmental protection

Compared to traditional heat treatment processing technology, HPP ultra-high pressure processing process consumes less energy and does not produce industrial "three wastes".

New Market Opportunities

For some products, HPP is the only technology allowed. HPP non-thermal processing technology has been particularly popular in recent years and is sought after by consumers.

You may be concerned about these

You may be concerned about these