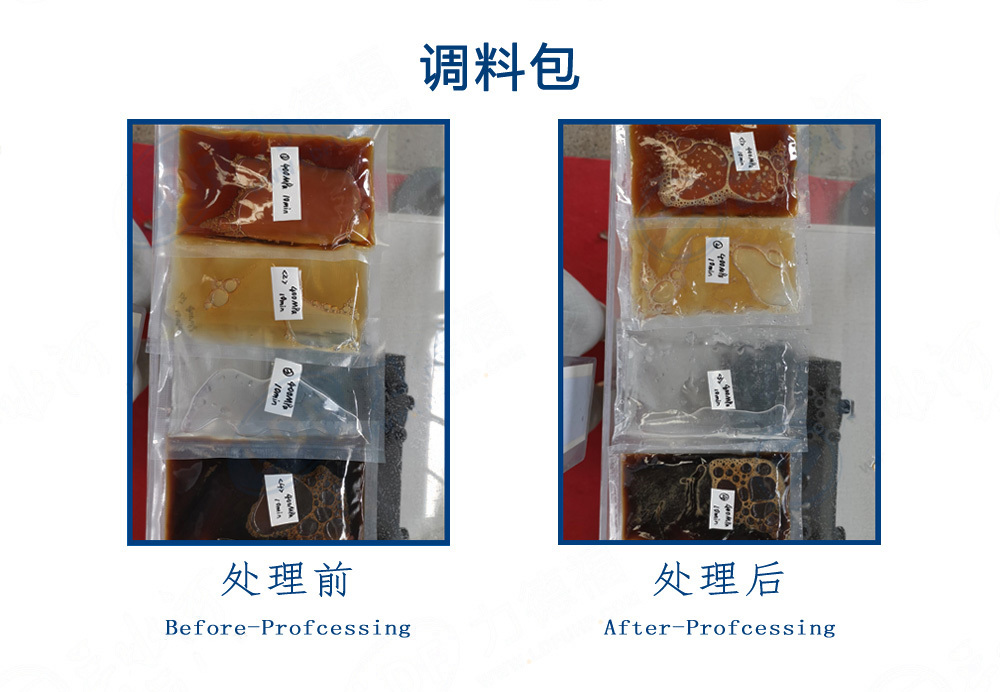

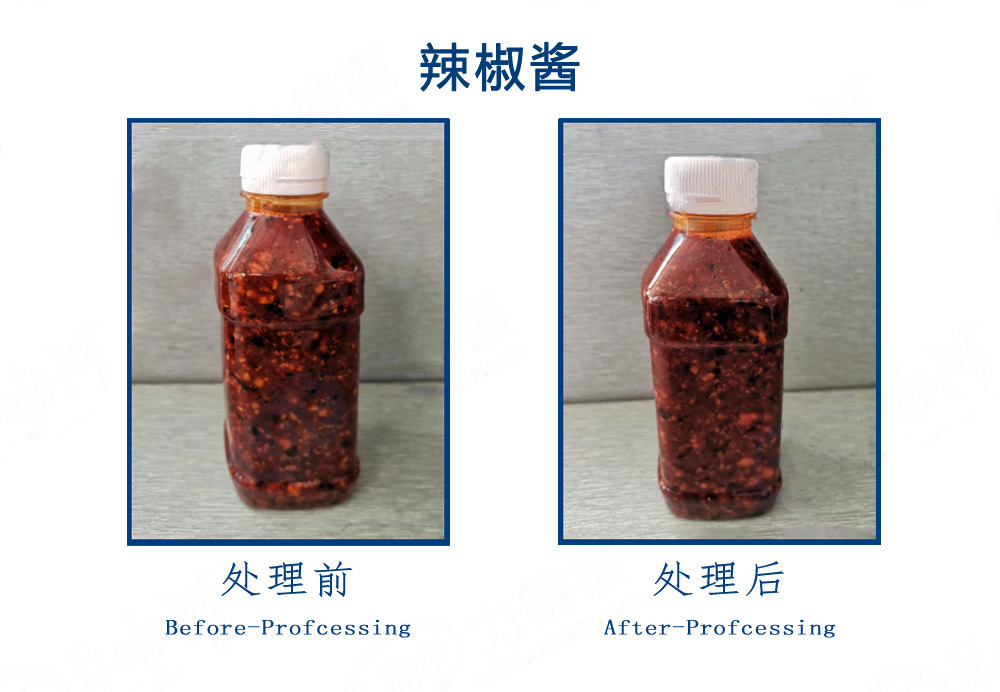

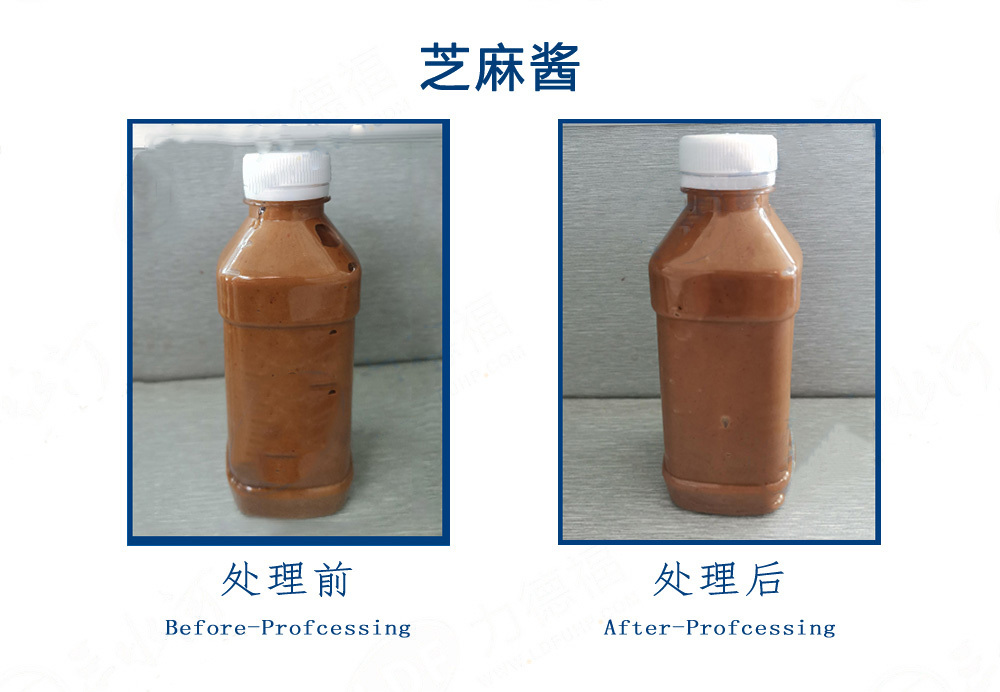

Sauce sterilization

HPP ultra-high pressure sterilization technology is widely used in sauce products. Due to the uniform pressure, thorough sterilization, and no drastic temperature changes during the entire sterilization process, it can perfectly preserve the original color, aroma, taste and nutrients of the sauce, keeping its taste in the best state. It is even more advantageous for developing low-salt and preservative-free sauce products.

Key benefits of HPP sauces

- Maintain the unique taste, aroma and nutrition of the sauce

- Complete sterilization, no need to add preservatives, safer to eat

- Can be used to develop sauce products with low salt, low sugar, no additives, and more nutritional value

Advantages of HPP ultra-high pressure sterilization

pure physical sterilization

HPP ultra-high pressure sterilization process without adding any chemical preservatives to maintain the original nutritional content and sensory properties of food

Extended shelf life

Because HPP technology can kill microorganisms and inhibit their reproduction, it can significantly extend the shelf life of food.

Efficient sterilization

Can kill all kinds of pathogenic bacteria in food, mold and yeast and other microorganisms to ensure the safety of food

Broad application industry

Suitable for fruit and vegetable juice, meat products, dairy products, fruit and vegetable puree, prefabricated vegetables and other food processing and preservation

Energy saving and environmental protection

Compared to traditional heat treatment processing technology, HPP ultra-high pressure processing process consumes less energy and does not produce industrial "three wastes".

New Market Opportunities

For some products, HPP is the only technology allowed. HPP non-thermal processing technology has been particularly popular in recent years and is sought after by consumers.

You may be concerned about these

You may be concerned about these