Industry Applications

Application of HPP Ultrahigh Pressure Process in Children's Food

UHP is a scientifically proven, cost-effective processing method that ensures the safety of fresh and refrigerated children's food while preserving the nutritional content, flavor and functional properties of the food.

Application of HPP process in beverages and fresh-cut fruits

Freshly squeezed taste, higher nutritional value, no damage caused by heating, longer shelf life and inactivated pathogens are the advantages that ultra-high pressure preservation technology brings to high-quality beverages and high-value-added fresh-cut fruits.

Application of HPP Ultrahigh Pressure Processing in Meat Products

Ultra-high pressure processing is an economical and effective method to protect meat products from pathogenic bacteria such as Listeria monocytogenes, Salmonella, pathogenic Escherichia coli and Campylobacter. Because the water pressure is distributed in all directions, the pressure transmission during the processing is uniform and immediate, and the effect on microorganisms is independent of the product size.

Application of HPP Ultrahigh Pressure Process in Plant-Based Food

HPP is a perfect non-thermal processing method to preserve the characteristics of plant-based foods, including but not limited to fruit and vegetable-based dips (guacamole, salsa, tzatziki, etc.), spreads, ready-to-eat salads (hummus, potato salad, etc.), marinades, condiments, artificial meats and non-dairy cheeses. HPP can inactivate foodborne pathogens and delay the growth of spoilage microorganisms, thereby extending the shelf life. Ensure food safety.

Application of HPP Ultrahigh Pressure Process in Dairy Products

Milk and eggs are important ingredients in a wide range of products. UHP is a scientifically proven, cost-effective way to keep these foods safe while preserving their nutritional content, flavor and functional properties.

Application of HPP Ultrahigh Pressure Process in Pet Food

HPP is a scientifically proven, cost-effective method for ensuring the safety of raw and freeze-dried pet food. As an excellent non-thermal minimal processing technology, HPP can destroy pathogens while protecting the integrity of vitamins and enzymes, thereby ensuring the biological activity of nutrients.

Fruit and vegetable juice sterilization

Ultra-high pressure sterilization technology is a non-thermal physical sterilization method. Fruit and vegetable juice treated with ultra-high pressure not only effectively extends the shelf life but also well preserves the fresh taste and nutrients of fruit and vegetable juice drinks. The main value of non-thermal processing lies in the development of subversive functional products that are natural, organic, and free of preservatives.

HPP ultra-high pressure sterilization technology can retain the original color, aroma, taste and nutritional ingredients of food to the greatest extent, without the need for preservatives, and can fully meet the market's demand for natural, additive-free, safe and nutritious baby food, bringing more development opportunities to companies. At present, ultra-high pressure sterilization uses terminal packaging sterilization, which can effectively kill bacteria, mold, yeast and other microorganisms, effectively protect baby food safety, and help baby food companies meet production standards.

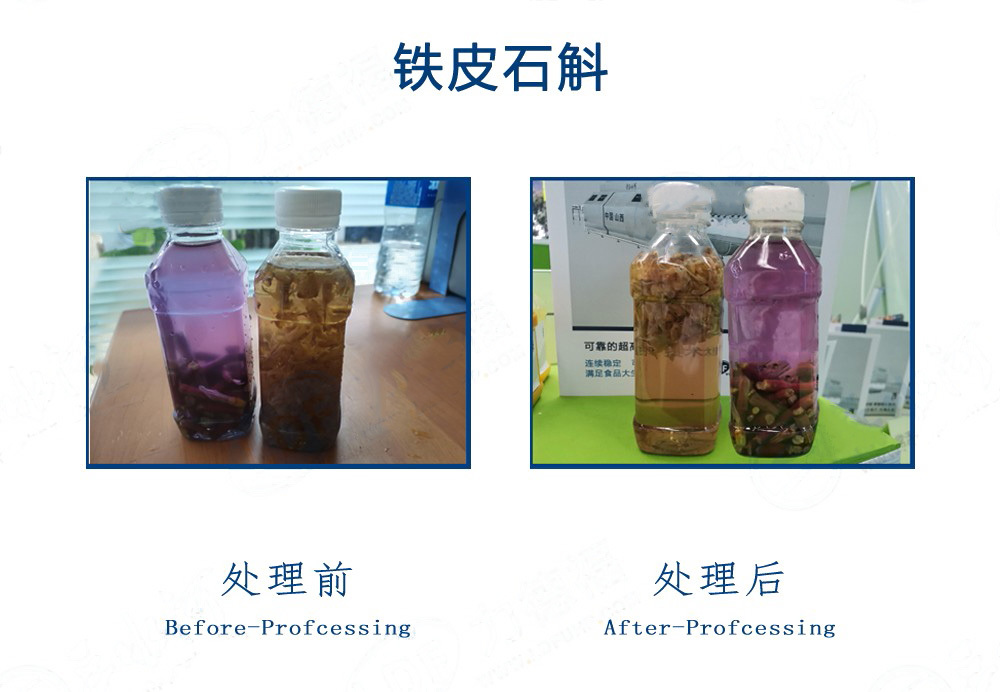

The emergence of HPP technology provides a new platform for scientific research, product development, and process innovation in biology and medicine. The raw materials of traditional Chinese medicine and health products mostly come from natural plants and animals, and many of their active ingredients are heat-sensitive. Ultra-high pressure can inactivate viruses and bacteria under low temperature conditions while fully retaining the activity of the active ingredients.