Industry Applications

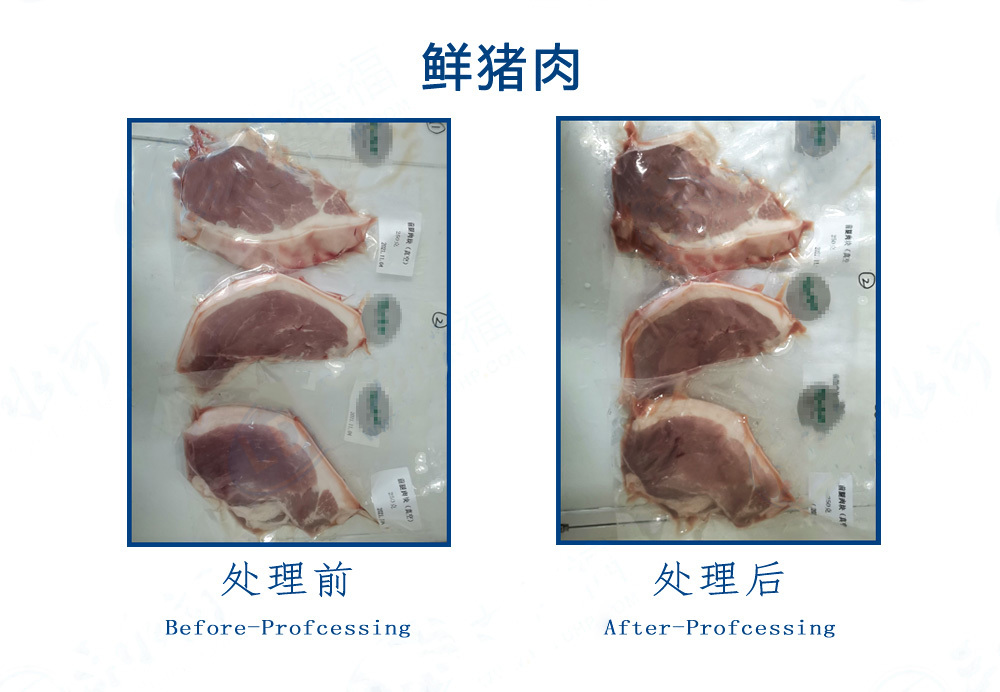

HPP ultra-high pressure sterilization technology can effectively inhibit microorganisms and pathogens in meat products to reduce the risk of raw food consumption, and also slow down the speed of mycin action, so there is no need to worry about Listeria, E. coli, Salmonella, etc. HPP products only need to be refrigerated (0℃-4℃) to effectively extend the shelf life of the product (2-5 times the original), solving the problems of nutrient loss and taste differences caused by freezing. Maintain the quality of fresh beef products and meet EU standards.

HPP ultra-high pressure sterilization technology is a dry non-thermal processing technology that can avoid the adverse effects of loss of nutrients and flavor changes caused by dry heat treatment, and meet people's pursuit of fresh, nutritious and healthy dairy products. Ultra-high pressure sterilization can maintain the activity of immunoglobulin and lipase, and can improve the coagulation properties of raw milk, which has promoted more types of safe and functional innovative dairy products to enter the market. High-temperature sterilization of fresh milk will not only inactivate beneficial ingredients such as active protein and ferrous lactate, but also convert calcium into a state that is not easily absorbed. The calcium in ultra-high pressure sterilized fresh milk is more conducive to being absorbed by the human body.

HPP ultra-high pressure sterilization technology is widely used in sauce products. Due to the uniform pressure, thorough sterilization, and no drastic temperature changes during the entire sterilization process, it can perfectly preserve the original color, aroma, taste and nutrients of the sauce, keeping its taste in the best state. It is even more advantageous for developing low-salt and preservative-free sauce products.

HPP ultra-high pressure technology can change the protein properties of the adductor muscles that control the opening of the shell in shellfish products, thereby achieving nearly 100% shell-meat separation of shellfish seafood, greatly reducing labor costs, and can effectively kill parasites and pathogenic bacteria in fresh aquatic products. The taste is fresh, tender and smooth, and the nutrition is fully protected, ensuring the safe consumption of fresh aquatic products and the high-quality sales of seafood products.

HPP ultra-high pressure technology can change the protein properties of the adductor muscles that control the opening of the shell in shellfish products, thereby achieving nearly 100% shell-meat separation of shellfish seafood, greatly reducing labor costs, and can effectively kill parasites and pathogenic bacteria in fresh aquatic products. The taste is fresh, tender and smooth, and the nutrition is fully protected, ensuring the safe consumption of fresh aquatic products and the high-quality sales of seafood products.