Application of HPP Ultrahigh Pressure Process in Plant-Based Food

UHP preservation is the perfect non-thermal processing method to preserve the characteristics of plant-based foods, which can be applied to plant-based foods including but not limited to fruit and vegetable-based dips (guacamole, salsa, Greek tzatziki, etc.), spreads, Ready-to-eat salads (hummus, potato salad, etc.), marinades, dressings, imitation meats, and non-dairy cheeses. HPP can inactivate foodborne pathogenic bacteria and delay the growth of spoilage microorganisms, thereby extending shelf life. Ensure food safety.

Without HPP ultra-high pressure processing, plant-based products can quickly spoil and create food safety risks. The use of ultra-high pressure processing can significantly extend the shelf life without adding preservatives or increasing sodium content, while ensuring food safety, and the nutrition, color and fresh taste are almost completely retained. This is because HPP Does not affect bioactive components and covalent bonds.

Given the acidity and Brix levels of most plant-based foods, they can generally be processed at lower pressures and with shorter holding times, which can result in lower unit costs.

Flexible plastic materials used to prepackage HPP foods must be waterproof and airtight and capable of being compressed by at least 15%. Certain specifications of materials, such as oxygen and moisture barrier properties, are critical to extending shelf life.

Because products undergo HPP processing after packaging, costly food safety recalls that can damage brand reputation can be avoided.

Advantages

• Fresh and natural taste - no heating, no additives required

• Scientifically proven – meets food safety regulatory requirements

• Non-thermal processing after packaging to ensure food safety - reduce cross-contamination

• Significantly extend shelf life - reduce food waste, facilitate cross-regional sales, and facilitate factory scheduling

• Improve and maintain product quality over longer shelf life

• Optimum sensory characteristics

Product concept evaluation and application services

Process Validation

Start with access to our experts at the HPP Application Center. We will provide comprehensive support from initial concept evaluation to internal inoculation challenge experiments, from product formulation, packaging guidance to HACCP establishment, aiming to accelerate your HPP product to market.

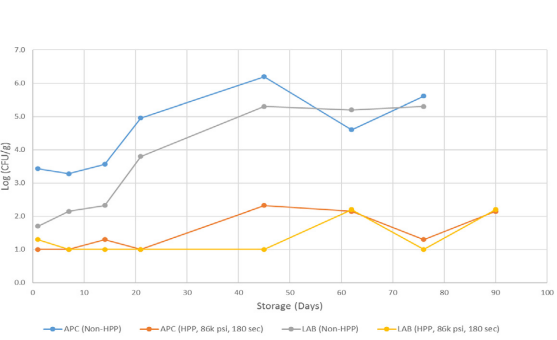

Effect of HPP on Microbiology

Effect of HPP on total colony count and lactic acid bacteria during the shelf life of mixed fruit and vegetable purees.

Apple, avocado, banana and pea puree

Advantages of HPP ultra-high pressure sterilization

pure physical sterilization

HPP ultra-high pressure sterilization process without adding any chemical preservatives to maintain the original nutritional content and sensory properties of food

Extended shelf life

Because HPP technology can kill microorganisms and inhibit their reproduction, it can significantly extend the shelf life of food.

Efficient sterilization

Can kill all kinds of pathogenic bacteria in food, mold and yeast and other microorganisms to ensure the safety of food

Broad application industry

Suitable for fruit and vegetable juice, meat products, dairy products, fruit and vegetable puree, prefabricated vegetables and other food processing and preservation

Energy saving and environmental protection

Compared to traditional heat treatment processing technology, HPP ultra-high pressure processing process consumes less energy and does not produce industrial "three wastes".

New Market Opportunities

For some products, HPP is the only technology allowed. HPP non-thermal processing technology has been particularly popular in recent years and is sought after by consumers.

You may be concerned about these

You may be concerned about these