Pharmaceutical Biology

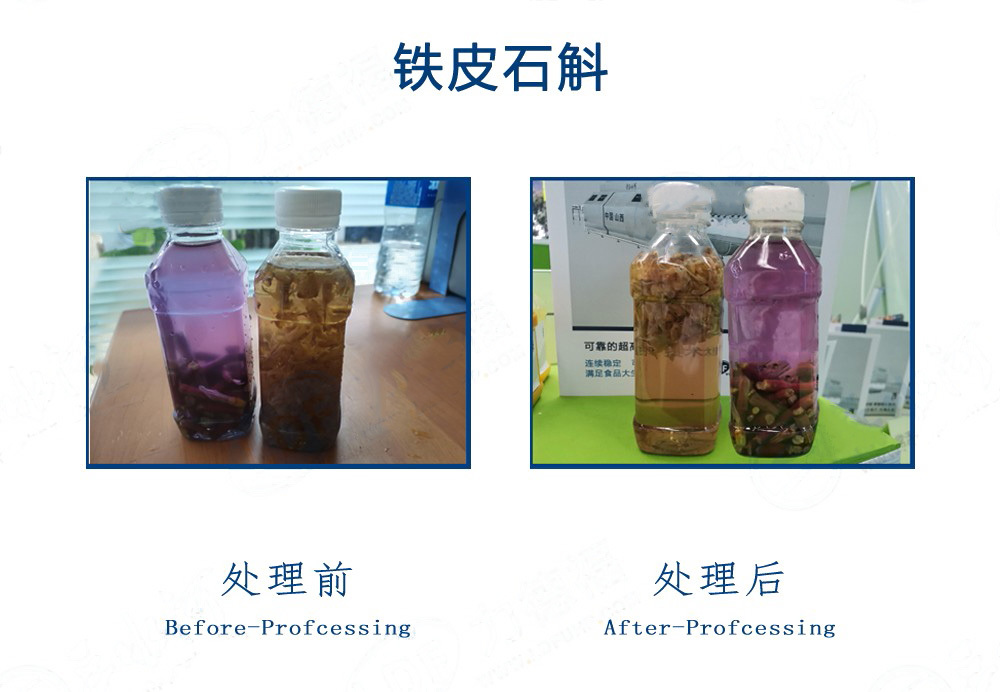

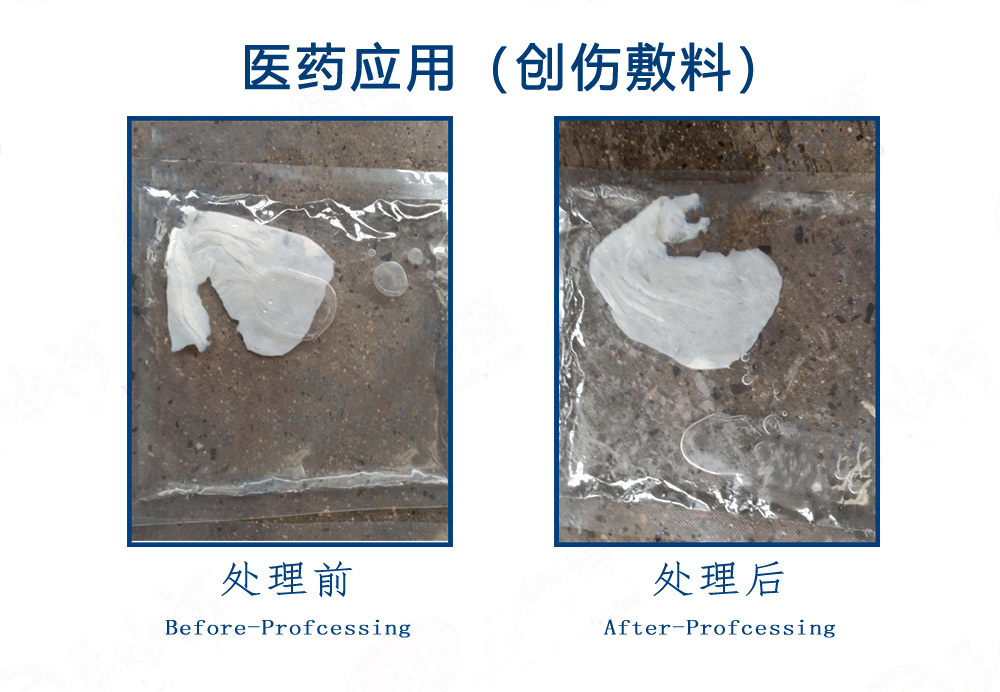

The emergence of HPP technology provides a new platform for scientific research, product development, and process innovation in biology and medicine. The raw materials of traditional Chinese medicine and health products mostly come from natural plants and animals, and many of their active ingredients are heat-sensitive. Ultra-high pressure can inactivate viruses and bacteria under low temperature conditions while fully retaining the activity of the active ingredients.

The main advantages of HPP pharmaceutical extraction

- Short extraction time, high extraction rate

- Low extraction temperature, retaining the biological activity of the extract

- The extract has good stability, and no precipitation, flocculation, turbidity, discoloration, etc. will occur during long-term storage

- The process operation is simple, safe, and has low energy consumption

- It can be used to extract the effective ingredients of dry Chinese medicine, low-temperature purification of fluids and pastes, crushing of genetically modified organelles, inactivation of viruses, vaccine extraction, non-destructive non-freezing refrigeration of human tissues, purification of artificial skin, high-pressure treatment of blood vessels, etc.

Advantages of HPP ultra-high pressure sterilization

pure physical sterilization

HPP ultra-high pressure sterilization process without adding any chemical preservatives to maintain the original nutritional content and sensory properties of food

Extended shelf life

Because HPP technology can kill microorganisms and inhibit their reproduction, it can significantly extend the shelf life of food.

Efficient sterilization

Can kill all kinds of pathogenic bacteria in food, mold and yeast and other microorganisms to ensure the safety of food

Broad application industry

Suitable for fruit and vegetable juice, meat products, dairy products, fruit and vegetable puree, prefabricated vegetables and other food processing and preservation

Energy saving and environmental protection

Compared to traditional heat treatment processing technology, HPP ultra-high pressure processing process consumes less energy and does not produce industrial "three wastes".

New Market Opportunities

For some products, HPP is the only technology allowed. HPP non-thermal processing technology has been particularly popular in recent years and is sought after by consumers.

You may be concerned about these

You may be concerned about these